Mirrors may be timeless design elements, but their longevity is anything but guaranteed. Behind the polished surface lies a delicate structure, glass, metallic coatings, and protective backings, that can degrade quickly when exposed to moisture, heat, or harsh cleaning agents. Without the right precautions, even a high-quality mirror can suffer from desilvering, corrosion, or visible surface damage that compromises both function and style.

Whether you're designing a luxury interior or simply preserving a favorite fixture, protecting mirrors requires more than routine upkeep. From smart placement and safe handling to technical solutions like edge sealing and pH-balanced cleaners, strategic care makes all the difference. In this blog, we’ll explore expert-backed methods to keep your mirrors pristine and performance-ready for the long haul.

Exploring Mirror Vulnerabilities

Before you can protect a mirror, it helps to know what makes it vulnerable in the first place. From how it’s built to what causes it to break down, understanding the underlying mechanics is the first step toward preventing long-term damage.

The Anatomy of a Mirror

At its foundation, a modern mirror typically comprises three main layers: a glass substrate, a reflective metallic coating, and a protective backing. The glass, usually soda-lime or low-iron float, provides structure and clarity. Silver is the most common reflective metal due to its high reflectivity (~95%) and neutral tone, while aluminum is used in more cost-sensitive applications for its durability and cooler hue.

In many cases, manufacturers add a copper layer over the reflective coating to inhibit oxidation, followed by one or more layers of protective paint. However, despite these barriers, mirror edges, especially on shaped designs like round, arched, square, or organic silhouettes, remain the most vulnerable due to thinner coverage and direct exposure. Therefore, for moisture-prone spaces like bathrooms or spas, mirrors with epoxy or safety backings offer much-needed reinforcement and durability.

Common Causes of Damage

Understanding a mirror’s construction helps clarify why certain conditions cause it to deteriorate. The leading causes of mirror damage include moisture intrusion, mechanical stress, thermal fluctuation, and chemical exposure.

Of these, moisture is the most prevalent, particularly in humid environments, where it infiltrates unsealed edges and breaks down the reflective layer, resulting in desilvering. In addition, mechanical damage, such as scratches from abrasive cleaning or careless installation, weakens the surface. Likewise, exposure to heat from nearby lights or vents can cause the glass and coatings to expand and contract, often leading to cracking or delamination.

Furthermore, chemical exposure is a major contributor to long-term damage. Cleaners containing ammonia, bleach, or acids can degrade the protective backing, while mounting adhesives or hardware made with reactive materials may introduce corrosion over time.

Fortunately, some mirrors are built to handle these challenges. For example, as shown above, Edward Martin’s Tristan Round Mirror in Polished Brass features a corrosion-resistant frame and durable backing, offering both protection and style, particularly in areas with high moisture or frequent use.

The Science of Tarnish and Desilvering

To better understand mirror degradation, it's helpful to distinguish between tarnish and desilvering, which are often mistaken for the same issue.

Tarnish is a surface-level reaction. It occurs when the silver layer reacts with airborne sulfur compounds, forming silver sulfide, a dull film that reduces reflectivity. This discoloration tends to appear more quickly in environments with poor air quality or high sulfur content.

By contrast, desilvering is deeper and more permanent. It usually begins at the mirror’s edges, where the protective backing breaks down. Moisture and contaminants enter through microgaps, accelerated by capillary action, and corrode the reflective layer, resulting in dark spots or flaking.

Ultimately, while modern mirrors benefit from copper-free coatings and multi-layer protective paints, no product is completely immune to these effects. For this reason, consistent environmental control, edge sealing, and selecting the right mirror for the setting are essential for long-term performance.

Strategic Placement and Installation for Longevity

Where and how you install a mirror can have just as much impact on its longevity as how you clean it. By taking a few smart precautions during placement and mounting, you can avoid the most common environmental stressors that quietly, but quickly, lead to damage.

Avoiding High-Humidity Areas

One of the primary contributors to mirror degradation is excessive moisture. Bathrooms, laundry rooms, and other damp areas accelerate corrosion when humidity seeps into edges or weak points in the backing, often resulting in desilvering.

To help prevent this, avoid placing mirrors directly above showers, bathtubs, or near frequent water splashes. In moisture-prone spaces, select mirrors rated for wet environments, those with double-layer epoxy or safety backings, and seal edges with a neutral-cure silicone or polyurethane to block water intrusion.

In addition to placement, effective ventilation is critical. Exhaust fans and dehumidifiers can keep relative humidity below 60%, while mirror demisters or heated pads in commercial settings help minimize surface condensation and preserve reflective quality.

Protecting from Direct Sunlight and Heat

Beyond moisture, prolonged exposure to sunlight and heat is another major contributor to mirror deterioration. UV rays degrade protective coatings over time, while thermal cycling, from nearby lights, radiators, or heat sources, can cause expansion, contraction, and eventual delamination.

To reduce these risks, avoid placing mirrors in direct line with intense sunlight, especially from south- or west-facing windows. If relocation isn’t feasible, UV-filtering window film or laminated glass with built-in UV protection can offer an effective buffer. Similarly, maintaining a safe distance, typically 6–12 inches, between mirrors and heat-emitting fixtures helps prevent localized thermal stress and material fatigue.

As an example, mirrors like Edward Martin’s Esmeralda Wide Mirror in Polished Brass, with its arched silhouette and durable frame, combine visual elegance with built-in resilience. As featured above, its placement in the featured setting demonstrates how thoughtful design can coexist with protective strategy.

Secure and Stable Mounting

Just as important as placement is how the mirror is mounted. Improper mounting is a frequent, yet easily avoidable, source of damage. Mirrors must be supported according to their weight and size using hardware that distributes load evenly, such as mirror clips, J-channels, or Z-bars. For adhesive installations, always use neutral-cure silicone or mirror-safe mastic to prevent chemical reactions with the backing.

Furthermore, in vibration-prone areas, such as near doorways or in commercial spaces, padding with foam or rubber helps absorb shock and protect against edge stress. All mounting surfaces should be dry, clean, and level to ensure consistent support. Lastly, for added durability and safety, consider specifying safety-backed mirrors, which include shatter-resistant films that help contain glass in case of impact.

Gentle Cleaning Practices for a Pristine Shine

Cleaning a mirror might seem simple, but the wrong approach can do more harm than good. With a few mindful techniques and the right materials, you can keep your mirror spotless without risking scratches or damage to the backing.

Choosing the Right Cleaning Agents

One of the first steps in effective mirror maintenance is selecting the right cleaning solution. Many commercial glass cleaners contain ammonia or alcohol, while effective at cutting through grease and fingerprints, they can be harmful over time, particularly if these substances seep into the mirror’s edges or backing. Ammonia, in particular, can accelerate the breakdown of protective paint layers and trigger desilvering.

Instead, it’s best to opt for pH-neutral solutions, such as a 50/50 mix of distilled water and white vinegar or a mild dish soap diluted in water. These alternatives clean effectively without compromising the mirror’s coatings. Moreover, using distilled water, especially in areas with hard water, helps prevent mineral deposits that can cloud the surface and prove difficult to remove without scratching.

Additionally, be sure to avoid abrasive powders, bleach-based cleaners, or acidic solutions, all of which can scratch the surface or corrode the mirror’s backing over time. As always, for specific care, maintenance, or general upkeep, it’s best to consult the manufacturer's guidelines to ensure you're using the most appropriate and safe cleaning approach for your mirror.

The Art of Streak-Free Wiping

Once you've selected a safe cleaning agent, the next step is technique. Proper wiping methods are just as important in preserving your mirror’s finish. A lint-free microfiber cloth is ideal, as it lifts dust and oil without leaving behind fibers or causing scratches.

Rather than spraying cleaner directly onto the mirror, which can lead to seepage, apply it to the cloth. Begin with gentle circular motions to distribute the solution, then follow up with horizontal or vertical strokes to remove residue. Finally, buff the surface with a dry section of the cloth for a streak-free shine.

For larger mirrors, a soft silicone squeegee can offer a more efficient solution. Simply start at the top and pull downward in smooth strokes, wiping the blade between each pass to prevent streaking.

Addressing Stubborn Spots Safely

Even with regular cleaning, some mirrors may develop more stubborn spots, such as dried toothpaste, hairspray, or water marks. In these cases, begin by softening the area with a warm, damp microfiber cloth.

Next, for residues like hairspray or adhesives, apply rubbing alcohol sparingly with a cotton swab, carefully avoiding the edges to prevent damage to the backing. If mineral deposits are the issue, a paste of baking soda and distilled water can be gently applied with a soft cloth. Use light pressure and rinse thoroughly with distilled water to ensure a clean finish without leaving behind film.

Lastly, and most importantly, never use razor blades, scouring pads, or steel wool. Though they may seem effective in the short term, they can leave micro-scratches that diminish clarity and collect dirt over time, ultimately undermining the mirror’s visual appeal.

Proactive Protection and Preventative Measures

Once your mirror is in place and properly maintained, the next step is making sure it stays protected for the long haul. Through a few smart, preventative measures, you can shield it from gradual wear that often goes unnoticed until it's too late.

Backing Protection and Sealing

One frequent failure point in mirrors is the deterioration of the reflective backing, typically due to moisture or chemical intrusion. This is especially true at the edges, where protective coatings tend to be thinnest. To counter this, applying a neutral-cure silicone or polyurethane edge sealant provides a waterproof barrier, helping block capillary action that draws in moisture or cleaning agents.

Moreover, for added protection in high-humidity environments like bathrooms or saunas, it's advisable to choose mirrors with copper-free backings and multi-layer paint systems. These advanced constructions mitigate the risk of galvanic corrosion and enhance overall durability. When specifying mirrors for such spaces, always confirm they meet ASTM C1503 standards for moisture and chemical resistance.

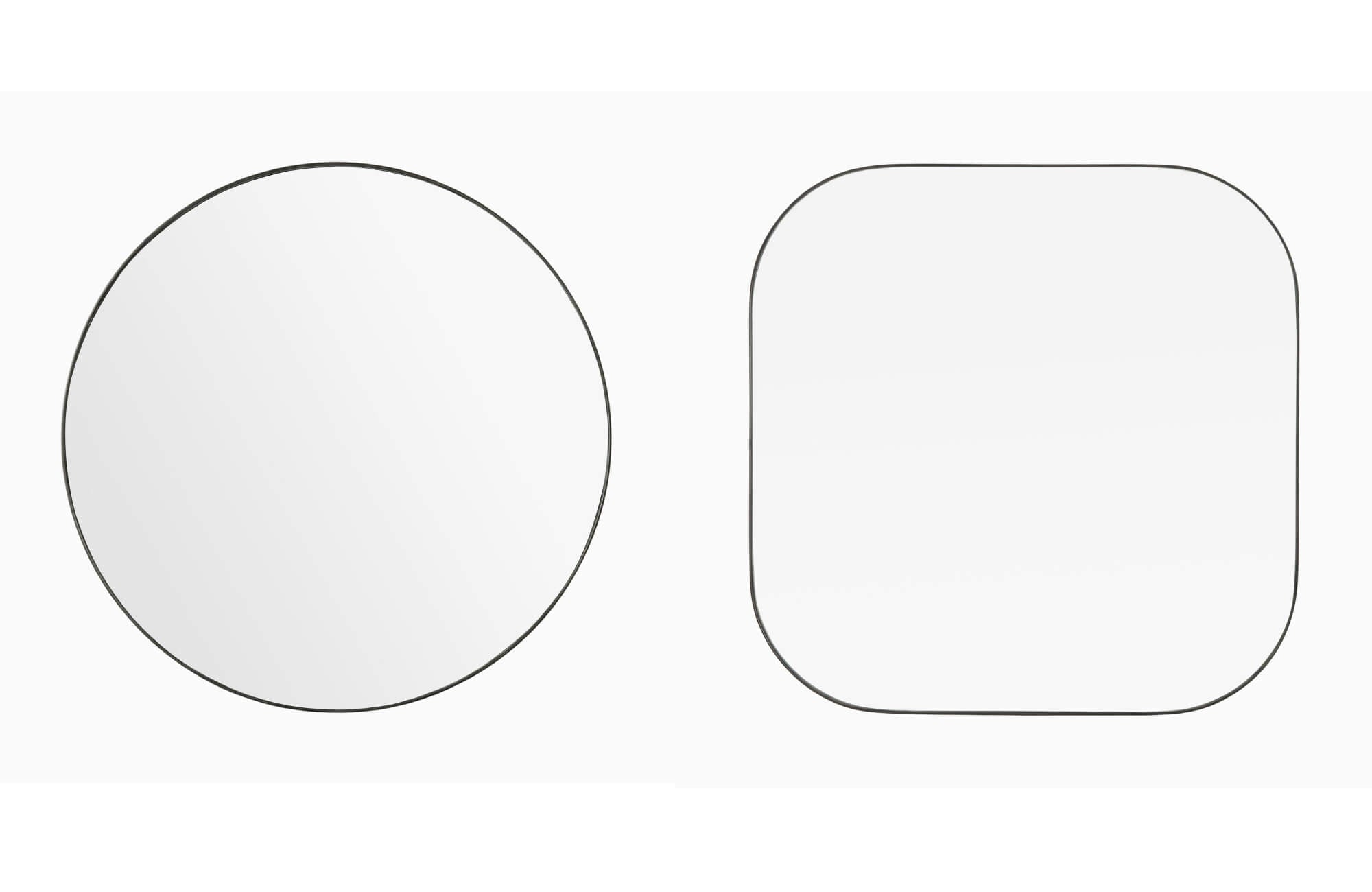

As an example, mirrors like Edward Martin’s Tristan Square Mirror in Rustic Black combine functional resilience with design sophistication, making them an excellent option for both damp environments and visually demanding interiors, as displayed above.

Using Protective Coatings and Films

In addition to sealing, protective coatings and surface films offer an extra line of defense. Clear epoxy or polyurethane coatings can be applied to the mirror’s backside to bolster resistance against moisture and oxidation. Furthermore, in commercial or busy settings, safety-backed mirrors with vinyl or PET film help prevent shattering and limit water penetration.

On the front-facing surface, enhancements such as anti-shatter films, scratch-resistant coatings, and UV-protective layers can help mitigate physical wear and sun damage. These treatments are especially valuable in environments like gyms, salons, and hospitality venues, where mirrors are exposed to frequent handling and variable lighting. Whenever possible, opt for factory-applied treatments. These typically outperform aftermarket options in both adhesion and durability, offering long-term reliability with minimal maintenance.

Regular Inspections and Early Intervention

Finally, protection isn't a one-time task; it requires consistent attention. Conducting visual inspections every 3–6 months is a smart way to detect early signs of damage, such as edge discoloration, flaking paint, or fading reflectivity. Focus particularly on corners and mounting points, where environmental stress tends to concentrate.

If issues arise, reapplying edge sealant, improving ventilation, or replacing reactive adhesives can prevent the problem from worsening. Additionally, decorative trim or framing can help conceal minor desilvering while offering renewed edge protection.

For larger installations or commercial settings, implementing a maintenance schedule, including personnel training and proper recordkeeping, can help preserve mirror condition and uphold warranty compliance over time.

Handling, Moving, and Storage Best Practices

Whether you're moving a mirror across the room or across the country, how you handle and store it can make all the difference. Because even the slightest pressure or poor packing choice can lead to cracks, chips, or long-term damage, taking the right precautions is essential from the start.

Safe Handling Techniques

As a starting point, it's important to recognize that mirrors are inherently fragile, particularly around the edges and corners. Most are constructed from annealed or tempered float glass, which performs well under compression but remains vulnerable to shattering under point pressure or torsional stress.

For safe handling, always carry mirrors vertically. Grip both vertical edges with two hands, and for larger pieces, enlist a second person to distribute weight evenly and prevent flexing. Avoid lifting mirrors by the corners or unsupported sides, which can easily lead to cracks.

Additionally, to prevent fingerprints, smudges, or chemical transfer from skin oils, wear cotton or nitrile gloves. Mirrors with polished or beveled edges demand extra caution, as their refined contours are more prone to chipping on impact.

In professional settings, tools like glass suction lifters with rubberized grips provide safer maneuverability, especially for large or irregularly shaped designs. Take Edward Martin’s Shirley Large Mirror in Antique Brass Iron, for instance; its sculptural form and organic curves, as seen above, require both visual sensitivity and structural care during installation.

Packing for Moving and Storage

Once handling is complete, the next step is proper packing. Poor packing is one of the most common causes of mirror damage during transport. Begin by wrapping the mirror in acid-free tissue or glassine to prevent surface abrasion and chemical reactions. Then, layer closed-cell foam or bubble wrap around the mirror, with extra focus on the edges and corners. Reinforce these vulnerable areas with cardboard edge protectors.

To add structure, sandwich the wrapped mirror between rigid boards such as MDF or corrugated cardboard. Secure the layers using stretch film or strapping, ensuring that no adhesive comes into direct contact with the glass or frame. Then, place the mirror upright in a snug mirror box or custom crate to prevent internal movement during transit.

When transporting multiple mirrors, never lay them flat or stack them directly on top of each other. Instead, store them upright with foam dividers in between and label all packages clearly as “fragile” with orientation indicators like “this side up.”

Optimal Storage Conditions

Beyond transport, how and where a mirror is stored can impact its longevity. To reduce the risk of corrosion, warping, or delamination, always store mirrors vertically at a slight angle, ideally 5 to 10 degrees, on padded A-frames or storage carts that offer stability and ventilation. Avoid placing mirrors directly on concrete or porous floors, as these can transfer moisture and lead to deterioration.

Equally important are environmental conditions. Maintain storage temperatures between 60–75°F with relative humidity between 40–60%. In unconditioned or fluctuating spaces, desiccants and dehumidifiers can help regulate moisture levels. Sudden changes in climate can cause condensation, which compromises mirror backing and accelerates desilvering.

Finally, avoid storing mirrors near off-gassing materials like certain paints, adhesives, or untreated wood, which may emit vapors that degrade the coatings over time. For long-term inventory, rotate mirror stock periodically and inspect for early signs of edge damage or backing failure.

To simplify these decisions, Edward Martin’s design consultation service offers one-on-one guidance from concept to delivery. For expert recommendations or inquiries, simply visit the Edward Martin Contact Us page. Our team is ready to help with product guidance, coordination, and tailored follow-up for a seamless design experience.

A Smarter Approach to Mirror Longevity

Protecting a mirror isn’t just about cleaning; it’s about understanding its vulnerabilities and taking thoughtful steps to avoid them. From sealing exposed edges and choosing the right mounting environment to handling with care and maintaining a balanced climate, small decisions can make a lasting difference. Whether you're preserving a showpiece in your home or outfitting a commercial space, Edward Martin offers expert guidance and refined solutions to help your mirrors stay flawless for years to come.